Materials

LDPE – Low-Density Polyethylene ![]()

Containers made of LDPE are soft and very squeezable which is perfect for lotions or gels. LDPE is not as hard, stiff, or strong as HDPE, but has good resistance to chemicals (alcohol OK), is a good vapor barrier, and is resistant to stress cracks. The material is more translucent than HDPE. Honey and mustard bottles are made of this material.

| Pros | Cons |

| Flexible and squeezable | Poor gas barrier |

| Chemical resistant (no solvents) | |

| Good water vapor and alcohol barrier | |

| Stress crack resistant | |

| Impact resistant |

HDPE – High-Density Polyethylene ![]()

HDPE is the most widely used material for plastic bottles. HDPE is harder, a little stiffer, and stronger than LDPE but is also slightly heavier. It has good impact resistance, generally better chemical resistance than LDPE, is a good moisture barrier, but is a poor odor barrier. It’s resistant to acids and caustics, but not compatible with solvents. Do not use with essential oils. The material is translucent. HDPE is used to make milk jugs and laundry detergent bottles.

| Pros | Cons |

| High impact and tensile strength | Poor gas barrier |

| Chemical resistant (no solvents) | |

| Good vapor barrier | |

| Stress crack resistant |

PET - Polyethylene Terephthalate ![]()

PET containers are crystal clear and are a good barrier to odor, gas, and moisture. It has a high degree of impact resistance and tensile strength. PET is highly resistant to dilute acids, oils, and alcohols, although acetones and ketones will attack PET. Soda bottles are made of this material because it’s a great gas barrier.

| Pros | Cons |

| Chemical resistant | Poor strong acid and base barrier |

| Good alcohol and solvent barrier | Fair moisture barrier |

| Good gas barrier | |

| Stress crack and impact resistant above room temperature |

PP – Polypropylene ![]()

PP shares many of the same characteristics as HDPE though PP is stiffer. The material surface of PP tends to scratch easily. PP is a good barrier to moisture, oil, and alcohol and is resistant to many chemicals. PP is used to make yogurt containers and syrup bottles.

| Pros | Cons |

| Excellent moisture barrier | Poor gas barrier |

| Good alcohol and oil barrier | |

| Chemical resistant |

| Characteristic | Material | |||

| LDPE | HDPE | PET | PP | |

| Clarity | ==½ | ==½ | ==== | == |

| Moisture Barrier | ===½ | === | ==½ | ===½ |

| Oxygen Barrier | = | = | === | = |

| Acid Resistance | ==½ | ==½ | ==½ | ==½ |

| Grease/Oil Resistance | === | === | === | === |

| Stiffness | = | == | ===½ | ==½ |

| Impact Resistance | ==== | ===½ | ===½ | =½ |

| Heat Resistance | == | === | =½ | === |

| Cold Resistance | ==== | ==== | === | =½ |

| Sunlight Resistance | == | == | === | == |

Neck Size

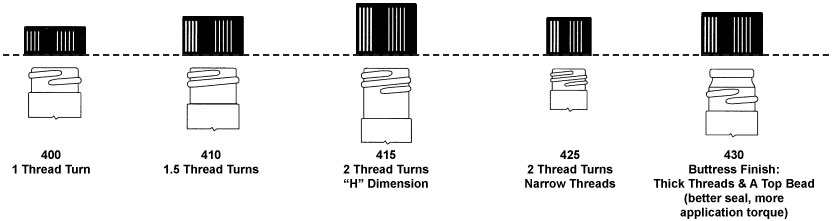

The Society of the Plastics Industry (SPI) has established uniform standards for plastic container neck sizes. A container and cap must have matching neck size to be compatible. The screw thread closure sizes are expressed as two numbers separated by a slash or dash, for example 20/410. The first number is the diameter in millimeters measured across the outside of the bottle’s threads or inside of the caps opening. The second number refers to the thread style as listed below:

400 – 1 thread turn

410 – 1½ thread turns

415 – 2 thread turns (tall neck)

425 – 2 thread turns (narrow threads)

430 – Thick threads/buttress finish

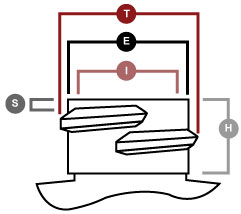

"T" Dimension: The outside diameter of the thread. The tolerance range of the "T" dimension will determine the mate between bottle and closure.

"E" Dimension: The outside diameter of the neck. The difference between the "E" and "T" dimensions divided by two determines the thread depth.

"I" Dimension: The inner diameter of the bottle neck.

"S" Dimension: Measured from the top of the finish to the top edge of the first thread.

"H" Dimension: The height of the neck finish. Measured from the top of the neck to the point where the diameter "T", extended down, intersects the shoulder.

Cap Seals

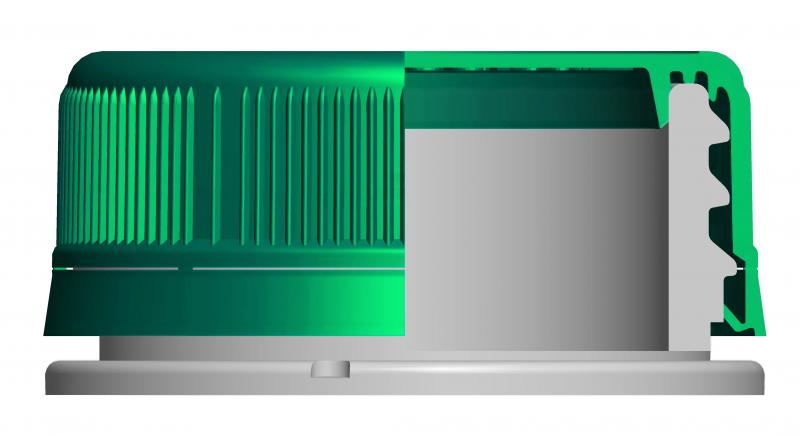

Land Seal

The land seal is a linerless sealing mechanism where a molded inner flange on the cap compresses against the bottle land or lip. Assuming a bottle lip is free of nicks, burrs or irregularities, the seal will not leak. In practicality, due to irregularities in manufacturing and defects from use, some bottles may seal better than others. The land seal is found on most dispensing caps.

F-217 Liner

An F-217 liner is a three-ply material with a low-density foam core sandwiched between two solid layers of low-density polyethylene. It provides an excellent seal for liquids. F-217 liners have great chemical resistance and a low moisture transmission rate. F-217 also has good taste and odor resistance. The F-217 liner is found on most non-dispensing caps.